Fabrication

McArthur BDC provide extensive fabrication services to support large projects as well as the capability to manage small maintenance and renewal jobs. With the support of the design team, we are able to support the development of a fabrication project from the design stage. The workshop is equipped with mig, tig and arc welders, working in mild steel, stainless steel and aluminium. Powder coating and galvanising is available for all steelwork.

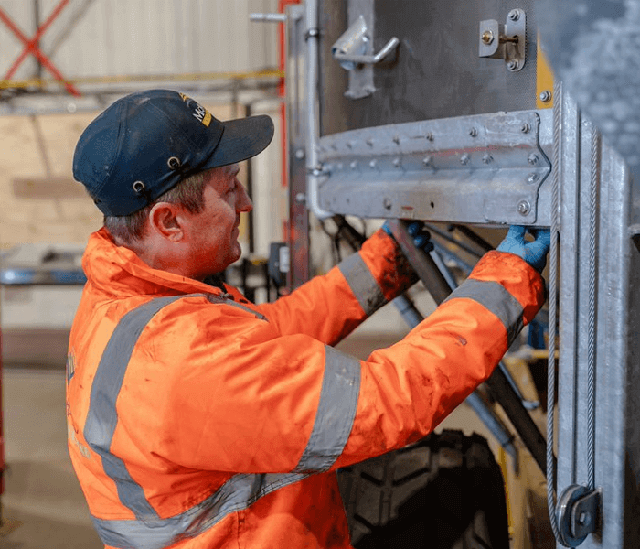

Sheet Metal Fabrication

Sheet metal work can be undertaken for a range of products and applications including, grain ducting, hoppers and machine refurbishment. Our skilled sheet metal workers can manufacture from drawings or, working with our in-house design team, develop the solution you require. The workshop is equipped with a 3m press brake (capacity 6mm mild and 5mm stainless) and 3m guillotine (capacity 8mm mild and 4mm stainless).

Precision Machining

Milling and turning can be undertaken in mild steel, aluminium, phosphor bronze and a range of more exotic materials. Common applications include shaft repairs, pulley and sprockets bored and keyed and manufacture of pins and bushes. The workshop is particularly capable at handling complicated, one-off repairs or renewals often for components that are out of production. The lathe has a machining capacity of 9” over saddle, 15” over bed and 80” between centres.