Our Process

In Partnership With

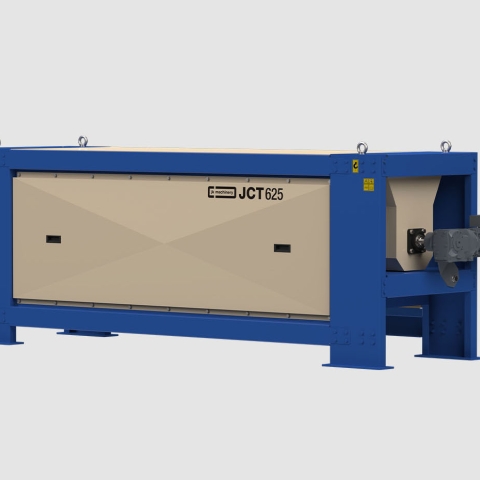

A colour sorter uses optical technology to separate grains based on their colour, shape, and size. High-resolution cameras capture images of the grains as they pass through the machine. The system detects any deviations from the desired specifications, such as discolouration, damage, or foreign objects. Once detected, air jets are used to eject the unwanted grains, ensuring only high-quality grains continue.

Common features include adjustable settings for colour, size, and shape, as well as real-time monitoring to allow for in operation adjustments. Many models also incorporate self-cleaning mechanisms to reduce maintenance time and improve operational efficiency.

When designing a colour sorter into a system, important considerations include the throughput capacity, the specific quality requirements of the grains, and how the sorter will integrate with other processing equipment. The layout of the processing plant is also key to ensuring the sorter fits seamlessly within the workflow. It is also crucial to ensure easy access for maintenance and calibration, and that the system is adaptable to future changes in product specifications or processing volumes. By carefully designing the system around the colour sorter, businesses can optimise grain quality, improve operational efficiency, and boost profitability.

Key Features

- Key Features

- High-resolution cameras for precise sorting

- Air jets for accurate ejection

- Adjustable settings for grain specifications

- Real-time monitoring and control features

- Self-cleaning for reduced maintenance time

Why Buhler

We work in partnership with Buhler to bring their colour sorter range to agricultural customers in Great Britain and Ireland. The SPARK colour sorter has been developed to deliver the quality and consistency of performance synonymous with Buhler at a price that will make it a standard piece of equipment on arable farms.