Our Process

In Partnership With

JK Machinery is a Czech manufacturer headquartered in Prague. The business has over thirty years of product development and manufacturing experience spanning both individual machines and complete turnkey plants for agricultural and food manufacturing customers. Alongside the production facility are test facilities in both the Czech Republic and UK that allow for the comprehensive testing of solutions, so customers can invest with confidence.

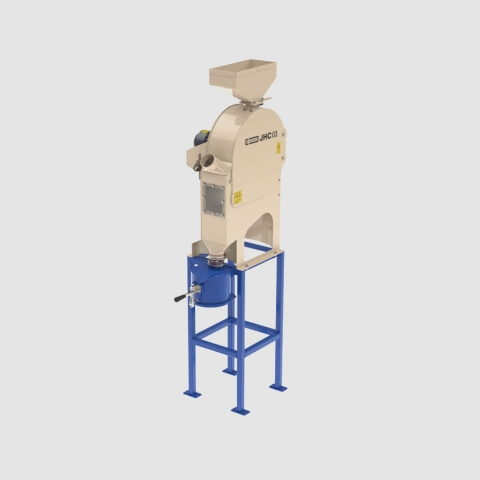

The JHP Horizontal Peeler cleans and dehulls grains as the central rotor pushes them towards a peeling stone. The abrasion between the grain and the stone dehulls the product and produces a mixture of kernels and hulls. An aspirator is mounted on the outlet to separate the light hulls from the kernels. For best results product should be cleaned and graded prior to dehulling, further separation of hulls from kernels is often required after the peeler.

The JHP Horizontal Peeler is designed for straightforward operation and maintenance. Easy to clean and maintain with few moving parts. The compact design and dust free operation allows it to be incorporated into both new and existing systems.

Key Features

- Gentle dehulling action

- Small footprint and compact arrangement

- Low power consumption

- Straightforward operation and maintenance

- Outlet aspirator for separation of hulls and light impurities

Why Horizontal Peeler

The horizontal peelers surface cleans and dehulls cereals including rye, oats, spelt, einkorn and emmer and pulses including beans, peas and lentils. The outlet aspirator removes hulls but further separation is typically required.

Why JK Machinery

Effective performance and simple design make the JHP Horizontal Cleaner a great option for processors surface cleaning and dehulling cereals and pulses. JK Machinery produces high quality equipment that delivers unmatched value for money.