Our Process

In Partnership With

JK Machinery is a Czech manufacturer headquartered in Prague. The business has over thirty years of product development and manufacturing experience spanning both individual machines and complete turnkey plants for agricultural and food manufacturing customers. Alongside the production facility are test facilities in both the Czech Republic and UK that allow for the comprehensive testing of solutions, so customers can invest with confidence.

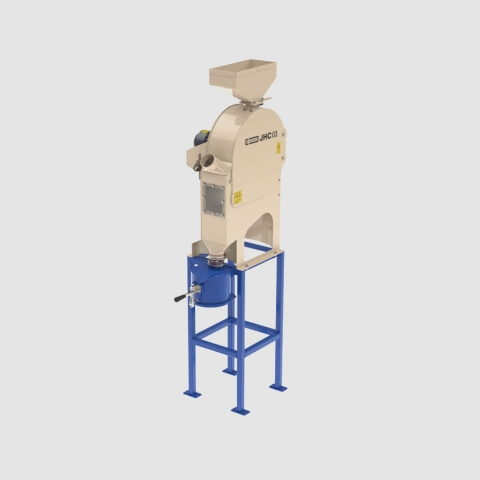

The JHI Impact Dehuller is fed via the top inlet which drops grain into the horizontally mounted rotor. The rotor accelerates the grain into an impact disc made from a range of materials such as abrasion resistant plastic or granite stone depending on application. The kinetic energy in the kernel separates the kernel from the hull on impacts and all the kernels and hulls drop thorough the two bottom outlets. Further separation is then needed to split hulls, kernels, broken kernels and un-dehulled grains.

The JHI Impact Dehuller is designed for straightforward operation and maintenance. Easy to clean and maintain with few moving parts. The motor that drives the rotor must be controlled by an inverter to allow the rpm of the rotor to be changed to achieve maximum dehulling efficiency, the best results are achieved when grain is graded prior to dehulling so grains of uniform particle size are processed together.

Key Features

- Suitable for dehulling grains where the hull is loosely attached to the kernel

- Small footprint and compact arrangement

- Low power consumption

- Simple adjustment for dehulling intensity

- Straightforward operation and maintenance

- Outlet aspirator for separation of hulls and light impurities

- Range of interchangeable impact disc materials for different grains

Why Impact Dehullers

The impact dehuller is effective for a range of cereals such as oats, spelt, einkorn and emmer and oilseeds including sunflower, hemp, camelina and oilseed rape where the kernel is not firmly attached to the hull.

Why JK Machinery

The JHI Impact Dehuller delivers effective performance and robust design making it suitable for regular use in commercial processing operations. JK Machinery produces high quality equipment that delivers unmatched value for money.