Our Process

In Partnership With

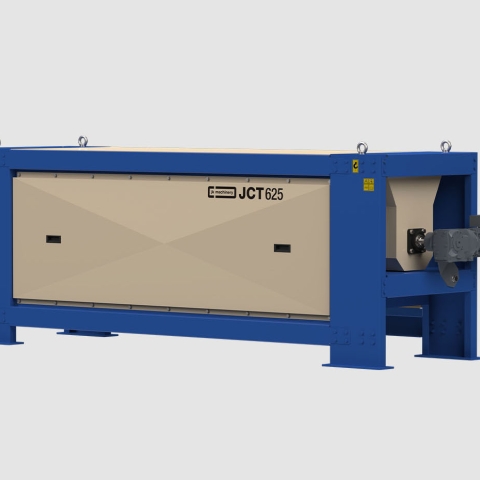

JK Machinery is a Czech manufacturer headquartered in Prague. The business has over thirty years of product development and manufacturing experience spanning both individual machines and complete turnkey plants for agricultural and food manufacturing customers. Alongside the production facility are test facilities in both the Czech Republic and UK that allows for the comprehensive testing of solutions, so customers can invest with confidence.

The JGD Destoner consists of an inclined vibrating wire mesh deck which air passes through. The combination of vibration and airflow causes the heavier impurities and lighter grains to separate into two layers, the heavier material being the impurities and the lighter material the cleaned product. The heavier impurities sink to the bottom and then move to the high outlet due to the contact with the vibrating wire mesh. The lighter grain flows down to the lower outlet.

The JGD Destoner is designed for straightforward operation and maintenance. Adjustment of incline, strength of vibration and airflow gives the operator a high degree of control to ensure the best results are achieved. Machines can be fitted with air recirculation to re-use up to 90% of the process air reducing the size of cyclone or filters required.

Key Features

- Highly efficient use of process air

- Small footprint and compact arrangement

- Low power consumption

- Straightforward operation and maintenance

- Easy adjustment of process variables

- Dust free operation

Why Destoners

The destoner’s fluidised bed allows the separation of materials to a very high degree of accuracy by specific weight. It is designed to remove stones and other heavy materials from combinable crops prior to further processing.

Why JK Machinery

Effective performance and simple design make the JGD Destoner a great option for processors. JK Machinery produces high quality equipment that delivers unmatched value for money.